Aloecore

We introduce the design concept and materials of electric vehicle motors to manufacture high standard motors for our fans.The motor adopts Essex brand 200 ℃ resistance wire, N48SHT magnet, and can withstand 170 ℃. Before assembling the motor, each motor core must pass a withstand voltage test of 2-2.2KV, and our motor has IP55 protection certification. Among them, our 1.5KW motor has a rated torque of 230N. M. Ensure the stable operation of the HVLS fan and provide maximum airflow to the fan. Provide 1.5KW and 0.8KW motors for the HVLS fan industry or other industries.

Application

Aloecore

| Model | Power | Torque | Efficiency rate | Motor pole | Rotation | IP | Current | Motor Weight | Motor Diameter | Magnet Wire | Magnet Iron | Ground insulation | Pressurization Test standard |

| Core15 | 1.5KW | 230Nm | 81.50% | 44 | 60rpm | IP55 | 3.4A | 42.5KG | 400mm | Anti 200°C | N48SHT | 300mΩ | 2000V |

| Core8 | 0.8KW | 95Nm | 85.50% | 32 | 85rpm | IP55 | 2.8A | 25.5KG | 270mm | Anti 200°C | N48SHT | 300mΩ | 1500V |

Technical Parameter

PMSM motor

We introduce the design concept and materials of electric vehicle motors to manufacture high standard motors for our fans.

The motor adopts Essex brand 200 ℃ resistance wire and N48SHT magnet, which can withstand 170 ℃.

Motor movement

Before assembling the motor, each motor core must pass a 2-2.2KV withstand voltage test, and our motors have IP55 protection certification.

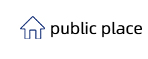

1500 motor temperature

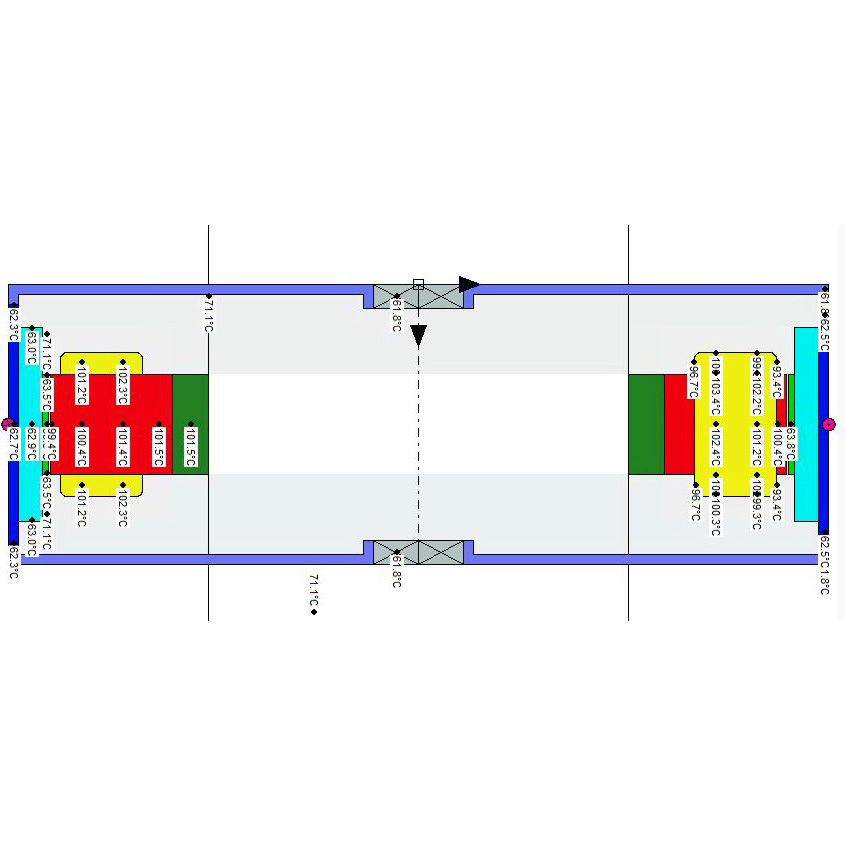

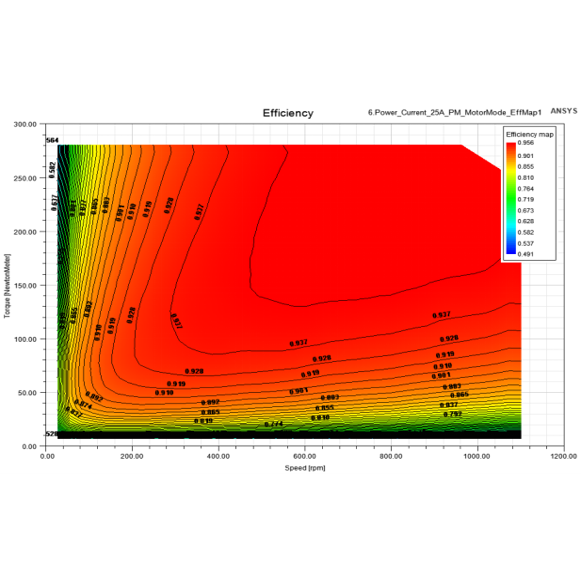

Efficiency simulation of core8,800W

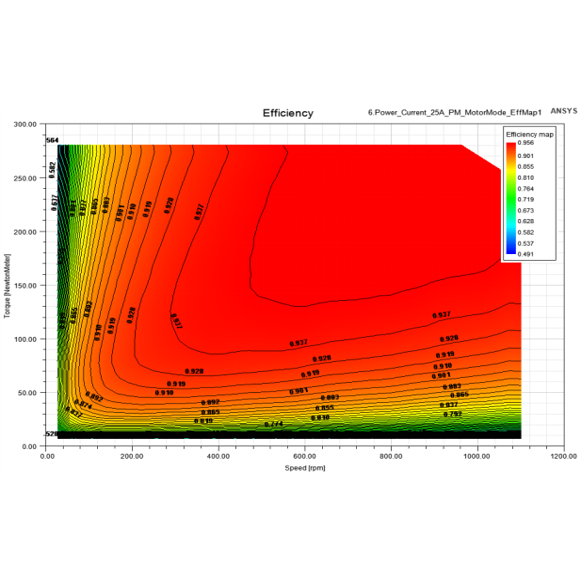

Efficiency simulation of core15,1500W

High grade magnetic steel N48SHT